Normally unusual attitudes in an aircraft involve an instructor or examiner putting the aircraft in some idiotic position in the sky like 60 degrees nose up and 120 degrees angle of bank. Then the hapless student has to recover to straight and level flight. Usually by reference to instruments, quite probably with the main attitude indicator failed.

In this case the phrase came to me when I was flat on my back on a mechanic’s creeper trolley looking up at the engine from below, checking wire locking and mounting rubbers. Don’t normally see it from this angle.

Yes, it’s annual inspection time once again.

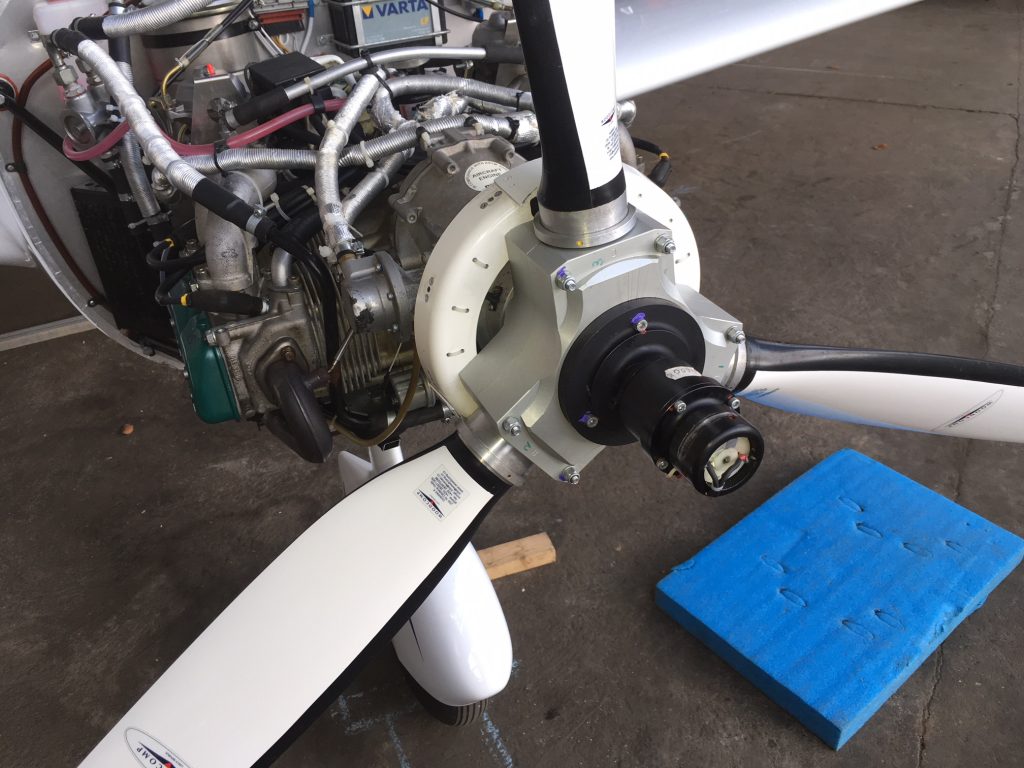

The propeller spinner came off to inspect the prop hubs and mechanism of the electrically operated pitch change mechanism, including the brushes which transfer the electrical signals from the (static) front of the engine to the (rotating) prop…

The wing tip lights came off to offer a view inside the composite wing structure – notice the aileron control linkage in the distance…

And the tail access hatch came off to enable the tail cone to be detached. This allows access to inspect and lube the elevator controls, rudder controls and pitch trip mechanism…

A close up of the trim mechanism. Note the wiring for a tail position light. The light is not fitted but the wiring is in place to make it easier in the future if required.

Just like last year, the seats and baggage lockers came out to allow access to control runs and the inside of the fuselage. Once everything was inspected and lubed up and checked it was time for the Light Aircraft Association inspector to come along and do his stuff. We have three at the airfield and another who pops in and out so we’re spoilt for choice.

It’s always a nerve wracking time for a couple of hours while the aircraft is gone over in meticulous detail, almost as bad as when the world’s coolest co-pilot was in surgery, but the aircraft passed and subject to a successful flight test will be good to go for another year.

We finally got the replacement wheel pant brackets from TL Ultralight and put them on when all the other panels were going on post-inspection. The first ones were too small, a slight confusion over sizes, but the correct ones came out of the Czech republic by courier. Excellent service from Ludek and Paul at the factory in Hradec Králové.

Now it’s just the renewal test flight to do. But first, back to work…