Or…I learnt about flying with a Rotax engine from that. Here we are at Sønderborg in Denmark a couple of years ago, basking in the midday heat. We had flown in from Groningen and were hoping to get all the way to Siljan Air Park in one day.

Flight Plan filed for the leg to Höganãs and aircraft refuelled, we jumped in and made our way to the end of the runway. With the heat, the plan was to climb as quickly as possible into the cooler air at 3000 feet or so…

I had just taken the photo above when we were assaulted by a strange smell and fluid running along the right side of the canopy. Brenda said with admirable calmness “It’s coming in!”

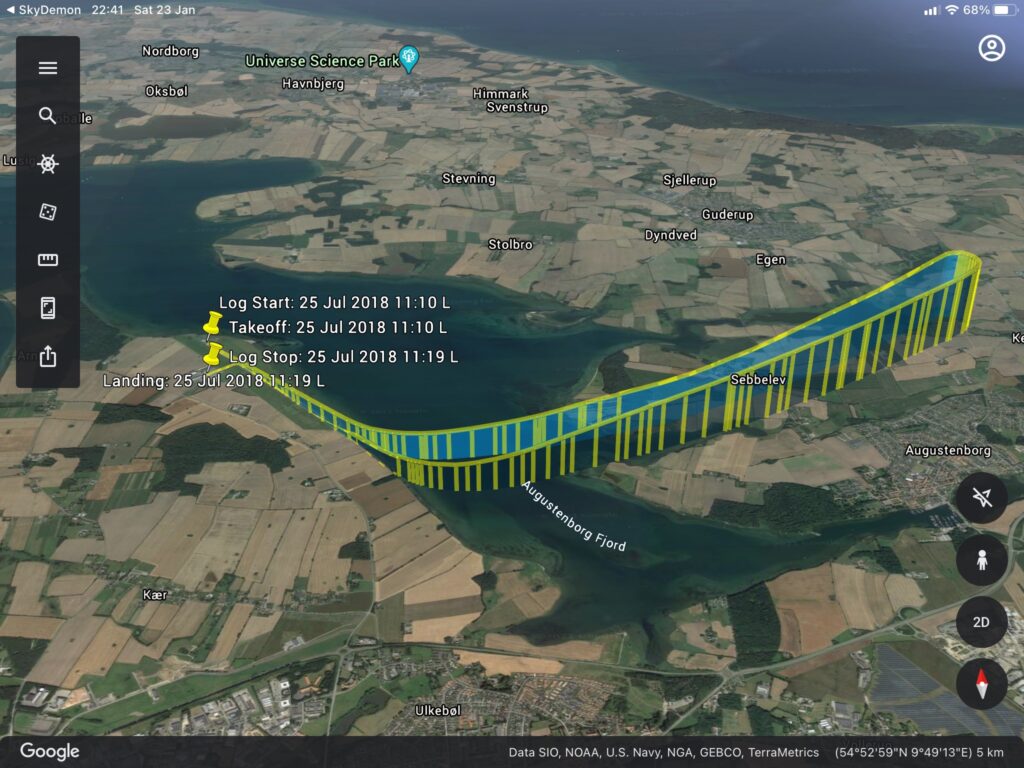

My immediate thought was “OIL LEAK!” so I throttled back and turned back towards the airfield. Checking the temperatures and pressures to confirm, we found that the oil pressure and temperatures were fine, so probably no leak – but the coolant temperature was high. Telling ATC that we had a problem, with no wind they cleared us to land in the opposite direction to our take-off. The Skydemon trace overlaid onto 3D Google Earth shows all nine minutes of the flight:

With the engine at low power the coolant temperature came down quickly, we landed OK and parked up in the same place we had vacated only 20 minutes or so before. After shutting down we pulled the cowlings to have a look. Here Chief Engineer Brenda inspects the coolant system overflow bottle – which was found to have lost some of its fluid.

I had made the rookie mistake of trying to climb quickly to the cooler levels. Full power equalled lots of heat output from the engine, and climb speed meant reduced airflow through the radiator. Combined with the high ambient temperature of midday in a summer heatwave the result was a rapidly rising coolant temp. The boiling coolant had started to expand out of the expansion vent on the top of the expansion bottle, and got sucked through the cowling gap and along the right side of the canopy. Luckily the stream passed over the open air vent, and alerted us by coming into the cockpit with its attendant funky smell.

We inspected the engine as it cooled. An Air Alsie Express engineer wandered over from the hangar to see if we needed any help, so we managed to scrounge some distilled water to replace the missing coolant. Just as a nosebleed always looks worse than it really is, we hadn’t lost very much fluid at all. It only required a “wee sploosh” to get the level back to in between the Min and Max markings on the bottle.

Once the engine had cooled down totally, I started up again while Brenda watched for any obvious leaks (it might not have been just from the overflow bottle), but all was OK. I shut down, we inspected the coolant system very closely and refitted the cowlings. Then we had to go into the terminal building again to refile the flight plan and have another cold drink from the machine.

On our second departure from Sønderborg I throttled back a bit at 500ft and did a long cruise climb up to the cooler levels. The coolant temperature stayed right where it should for the whole flight, and the rest of the trip up Sweden, and back five days later. I learnt about Rotax engines from that…

“Wee sploosh” is a recognised engineering term – Chief Engineer Brenda says so…